NEVALON FIBER — leading underground services for laying aerial fiber optic lines

High-performance installation of Stingray fiber optic lines, laying the last miles based on FDH and TOBY

NEVALON FIBER is a company specializing in the construction of fiber optic communication lines using the cable blowing method based on Stingray technology

Our services

Underground construction

underground laying of main pipelines, including drilling, trench digging, installation of microchannels, manholes

HDD drilling

trench digging, microtrench digging

installation of microchannels/microchannel bundles for aerial fiber optic lines

installation of hatches, pedestals, TOBY boxes

construction site restoration

Blowing and installation

pulling the main cable with air blowing fiber optic cable from the central trunk line to the customer's house

blowing Stingray fiber optic cable through microchannels

complete testing, grafting, tray organization

marking and testing OTDR/IL/RL

preparation of a complete package of implementation documentation

Distribution and connection

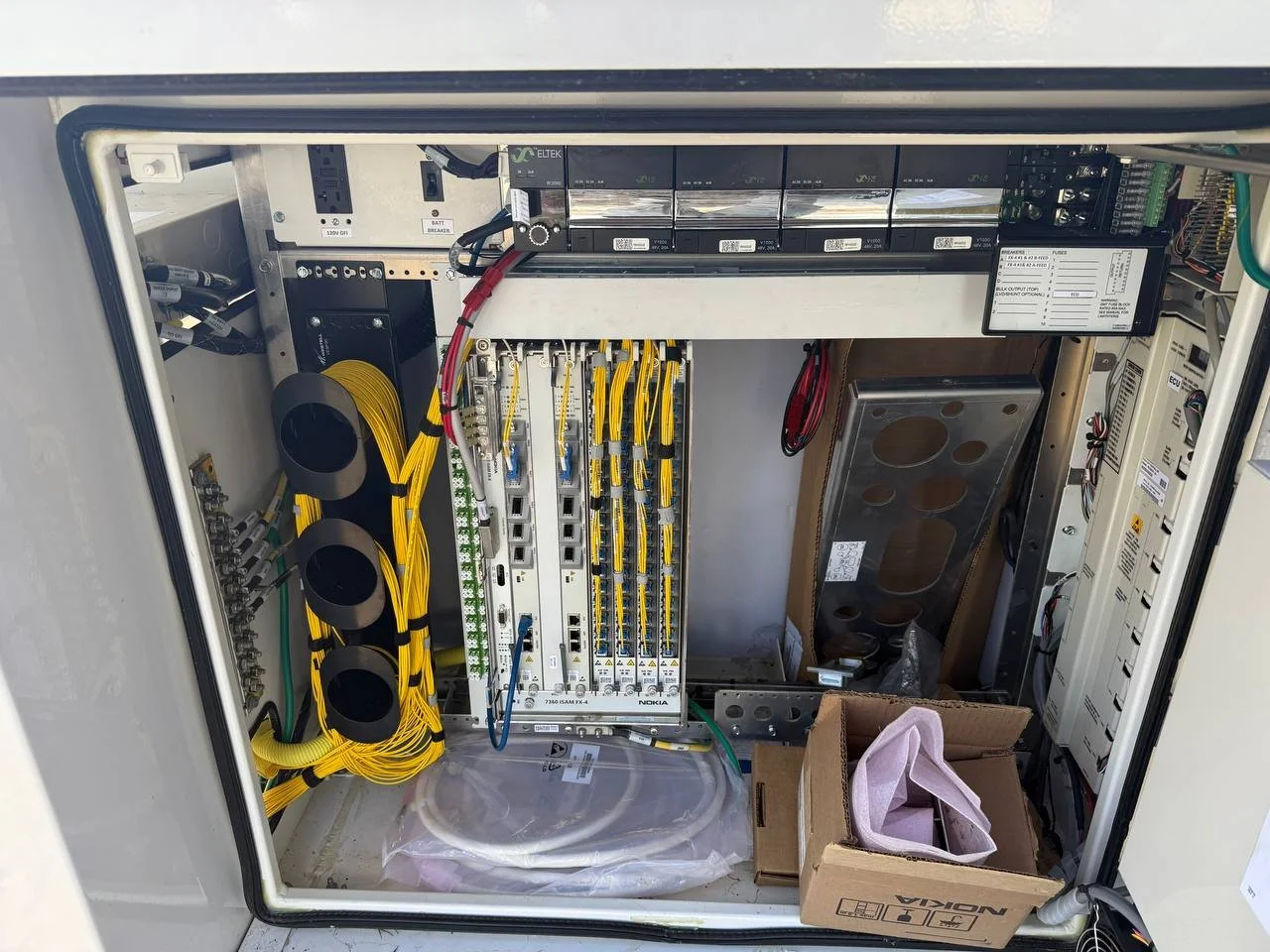

installation and connection of FDH cabinets, purging of distribution lines, configuration of NID/ONT

installation and connection of FDH cabinets

blowing distribution lines to MDUs and SFUs

installation from TOBY to homes

professional configuration of NID/ONT

Repair and maintenance

repair and maintenance: troubleshooting and repair, restoration of operation, sealing

fault finding, including excavation work

replacement of damaged microchannels and optical fiber

restoring blow-through capability, sealing

24-hour emergency repair service

Our advantages

Expertise in blowing air through fiber optic cables — trained teams that meet Hexatronic Stingray standards.

Quality control — complete OTDR/IL/RL test reports, proper labeling, and documentation of performance.

Speed and scalability — several teams, sectional blowing, our own equipment.

Safety and compliance—OSHA, MUTCD, local permits, and utility notification (811).

Last mile specialists — clean and accurate connections to residential premises with minimal obstacles.

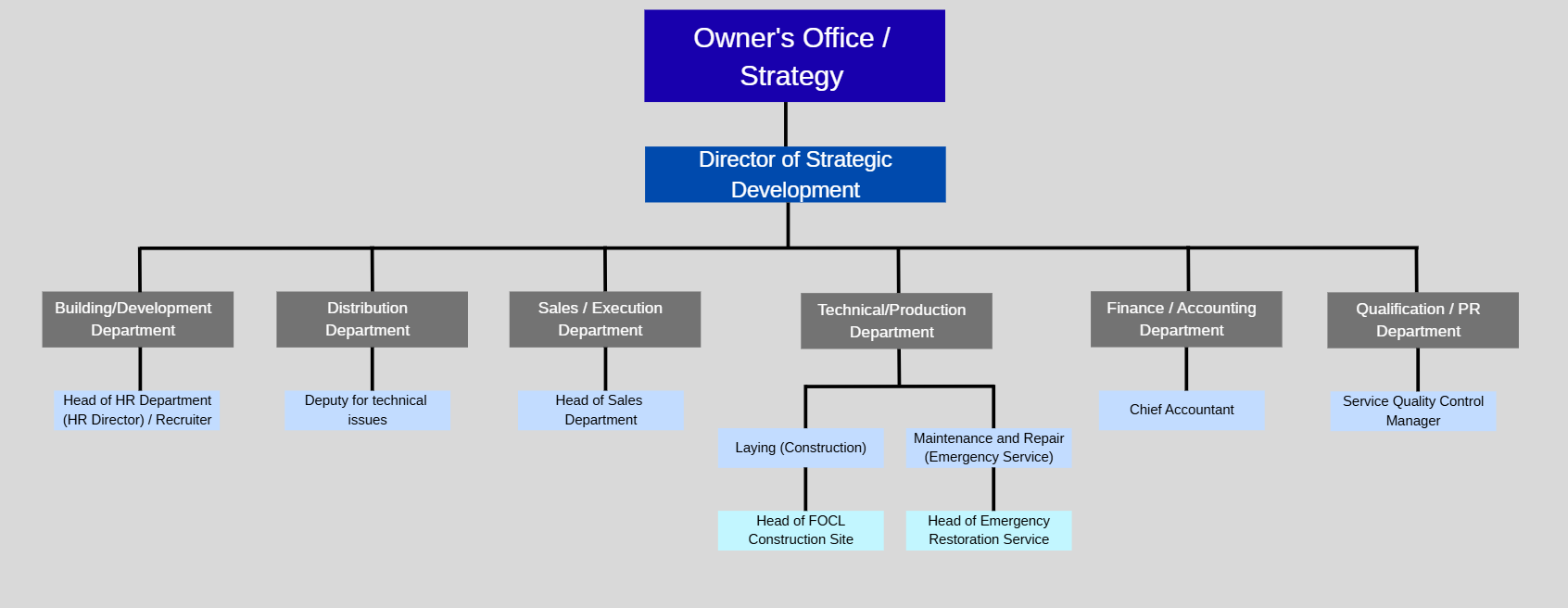

Company structure

Vision

Our vision is a world where our clients never have to worry about the quality of their connection, because we guarantee their optical networks are always performing at peak efficiency, 24 hours a day, 7 days a week.

Mission

To be the most reliable partner for businesses and the community where speed and continuity of communication are critically important.

Strategic Execution

We construct and commission cutting-edge fiber optic networks, strictly adhering to technical specifications and approved project designs. Our primary objective is to ensure impeccable installation quality that guarantees high-speed and uninterrupted connectivity. Our emergency response team provides instant communication restoration during outages, ensuring our clients maintain continuous operations in the modern digital landscape.

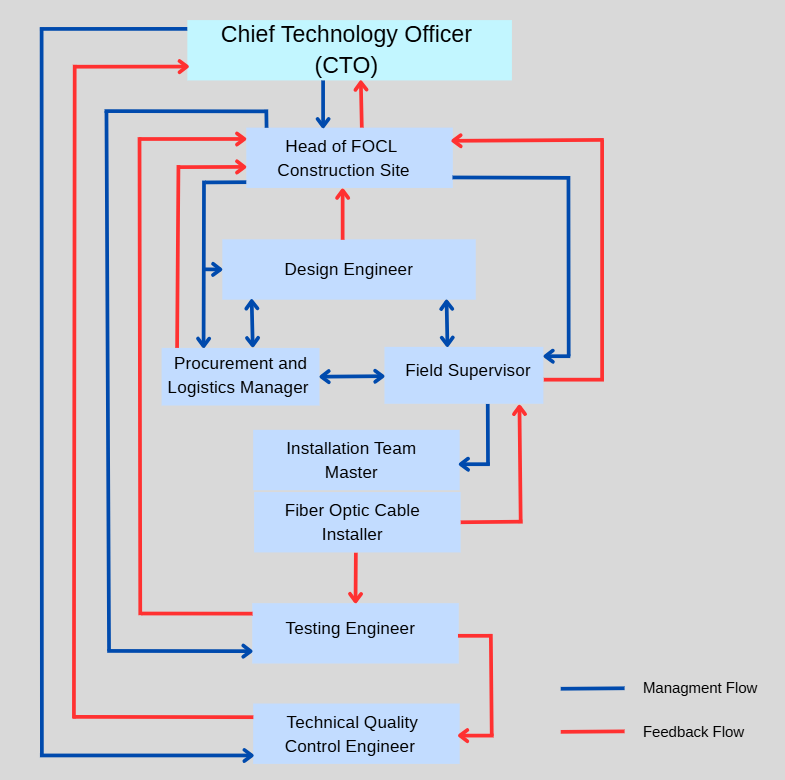

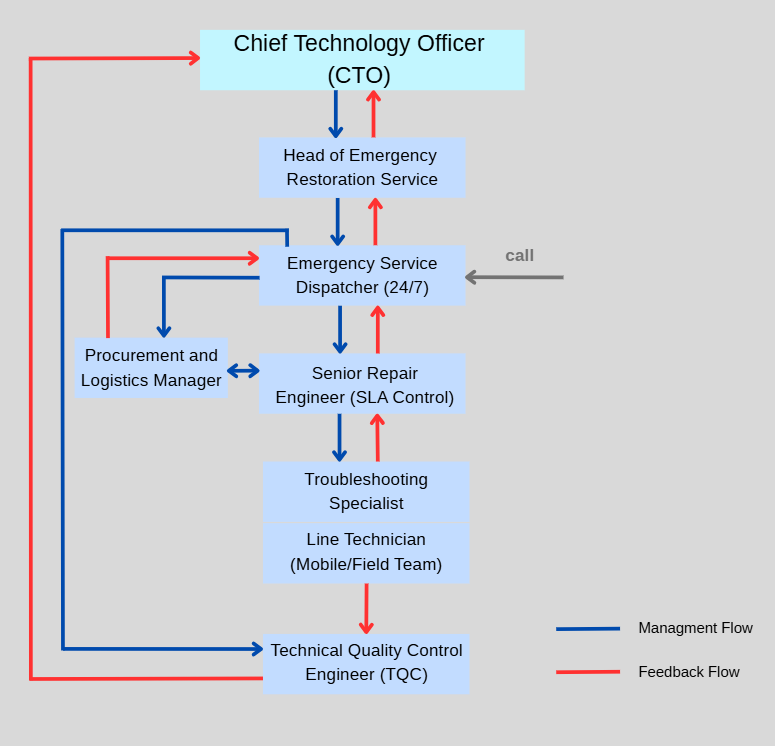

ORDER MANAGEMENT PROCESS FLOW

Prodaction

Maintenance/Repair

Our operational structure is built on a transparent, engineering-driven process that ensures reliability and consistency at every stage of fiber deployment and maintenance.

-

End-to-End Process Contro

Each step — from design and logistics to installation, testing, and quality verification — follows a defined chain of responsibility without duplication of functions.

-

Clear Roles and Tested Procedures

Every specialist works according to a role-specific instruction set, developed and refined over years of practical experience and analysis of real-world challenges.

-

Dual Communication Flow

A management flow guides project execution, while a parallel feedback flow enables immediate reporting, correction, and continuous improvement.

-

Separate Build and Maintenance Pipelines

Construction and emergency-repair operations operate through dedicated workflows, ensuring predictable project delivery and rapid response to service issues.

-

Confidence for the Client

Such structured coordination guarantees that each project stage is overseen by competent professionals and aligned with an integrated quality-management and timeline-control plan.

Problems we solve for our customers because we know what the consequences of a mistake could be

Inconsistency of work

The lack of control at various stages leads to errors in cable laying and connection.

Delays in connecting customers

The traditional approach with multiple contractors often results in downtime and dissatisfaction among end users.

Lack of documentary evidence of work performed

The customer has no clear evidence that the work was performed in accordance with the project documentation.

Ineffective quality control

Insufficient control during installation and testing increases the risk of damage and problems during operation.

Difficulty in coordinating work during unpredictable situations

Damage to cable lines by other construction companies or displacement of utility networks.

Errors in connections and line routing

The lack of control at various stages leads to errors in cable laying and connection.

Underground construction

What can happen if the work is performed by an unscrupulous contractor

-

Failure to observe the minimum bending radius, use of rough techniques, ignoring the fragility of fiber optics, lack of testing

-

Working in soft and wet soils requires special attention. Without this, collapses and water filling are possible, which can damage fiber optic cables.

-

Without prior coordination with utility services, geophysical surveys may damage gas, water, or electrical lines, causing emergencies.

-

Incorrect route planning, use of inefficient equipment, manual digging, lack of a step-by-step work schedule

-

The lines are being laid in violation of standards, without the appropriate permits, and with disregard for safety. This could result in fines from regulators.

Our advantages

-

Ensuring increased reliability and protection of cables, minimizing the risks of breakage and damage to the system

-

No negative impact on the external environment: we use horizontal directional drilling without forming trenches.

-

We are creating secure lines that will require fewer repairs in the future and reduce costs for customers.

-

We are creating secure lines that will require fewer repairs in the future and reduce costs for customers.

-

Underground installation has minimal impact on the landscape or aesthetics. We ensure concealed integration.

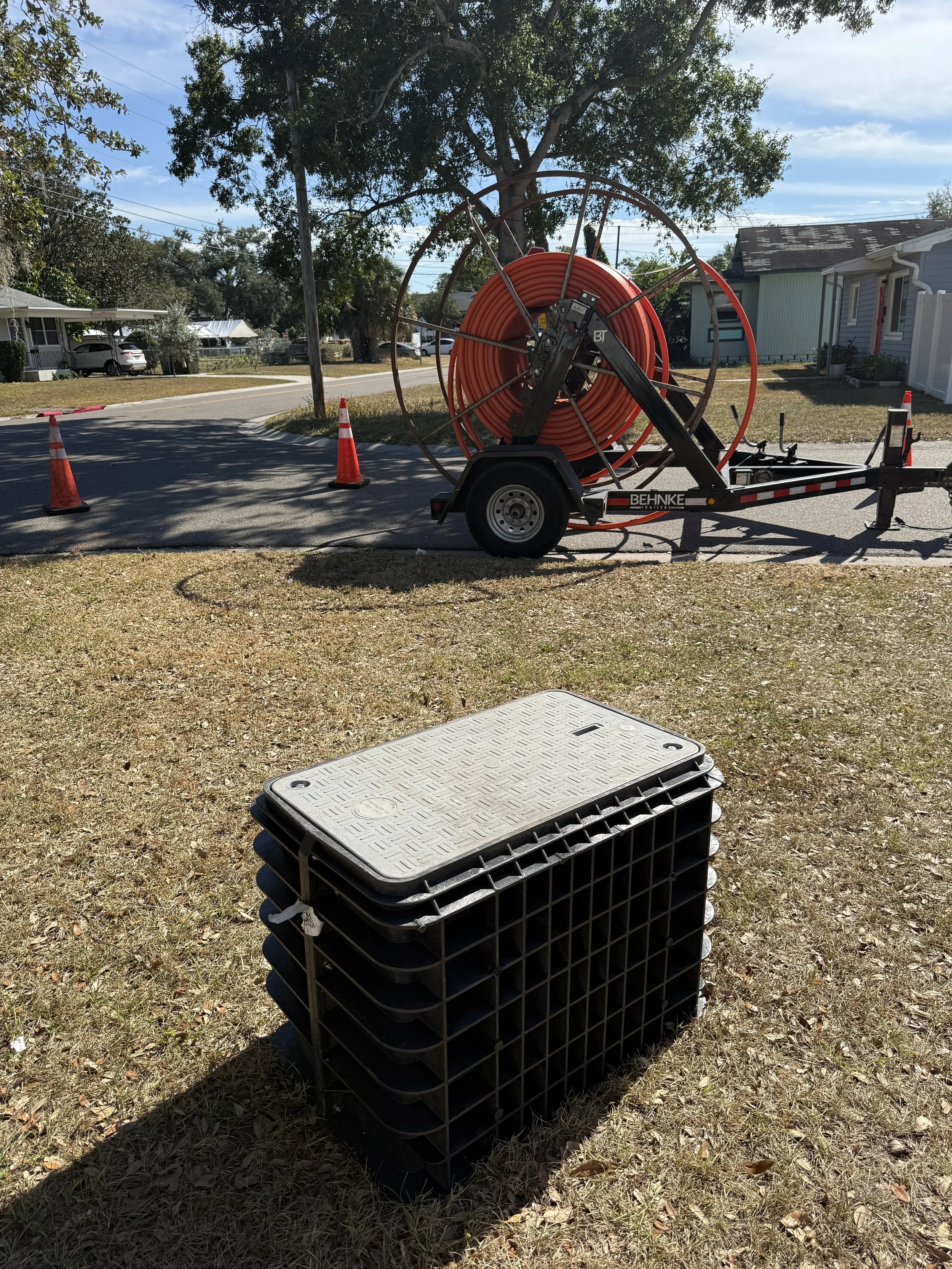

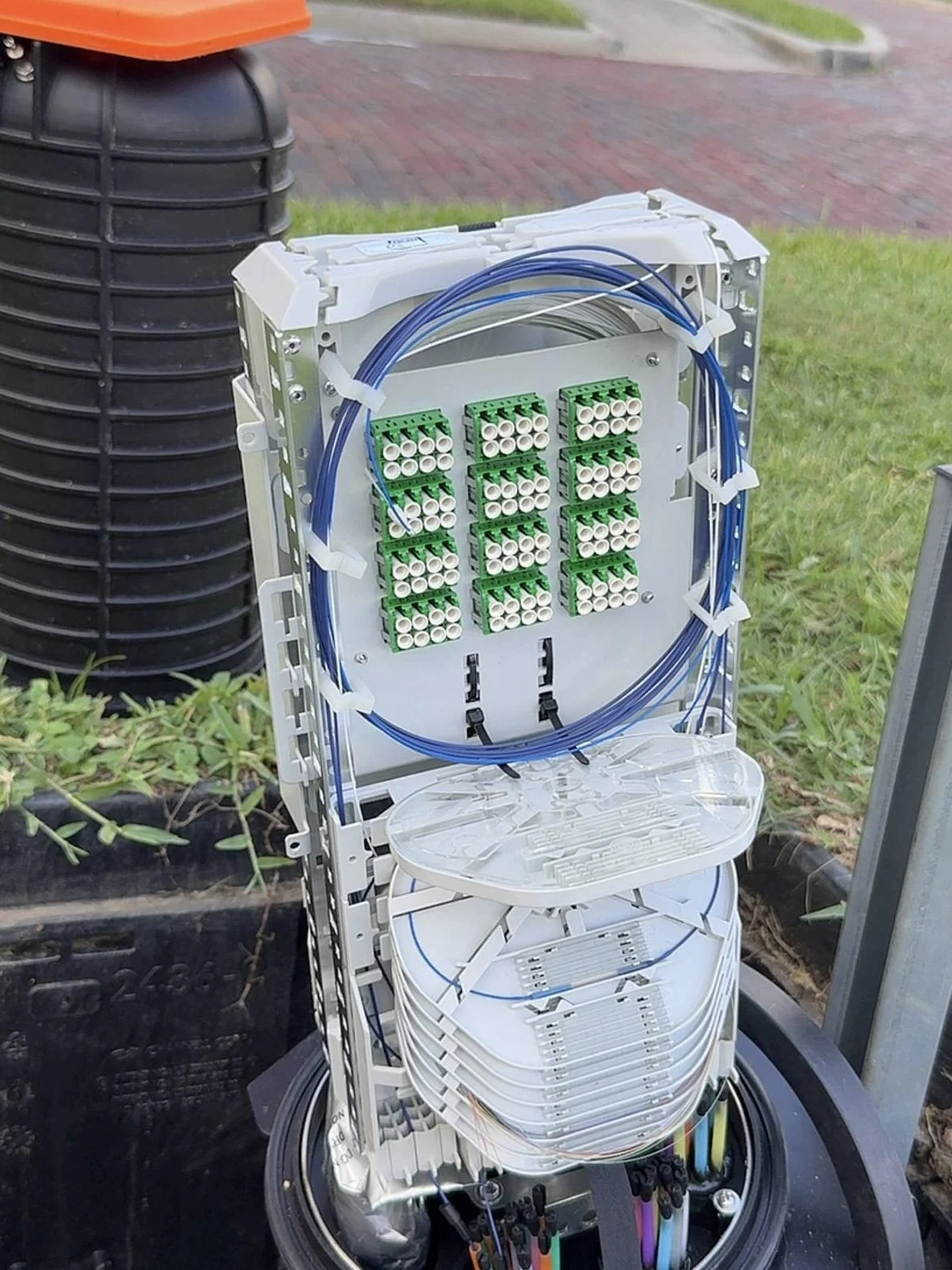

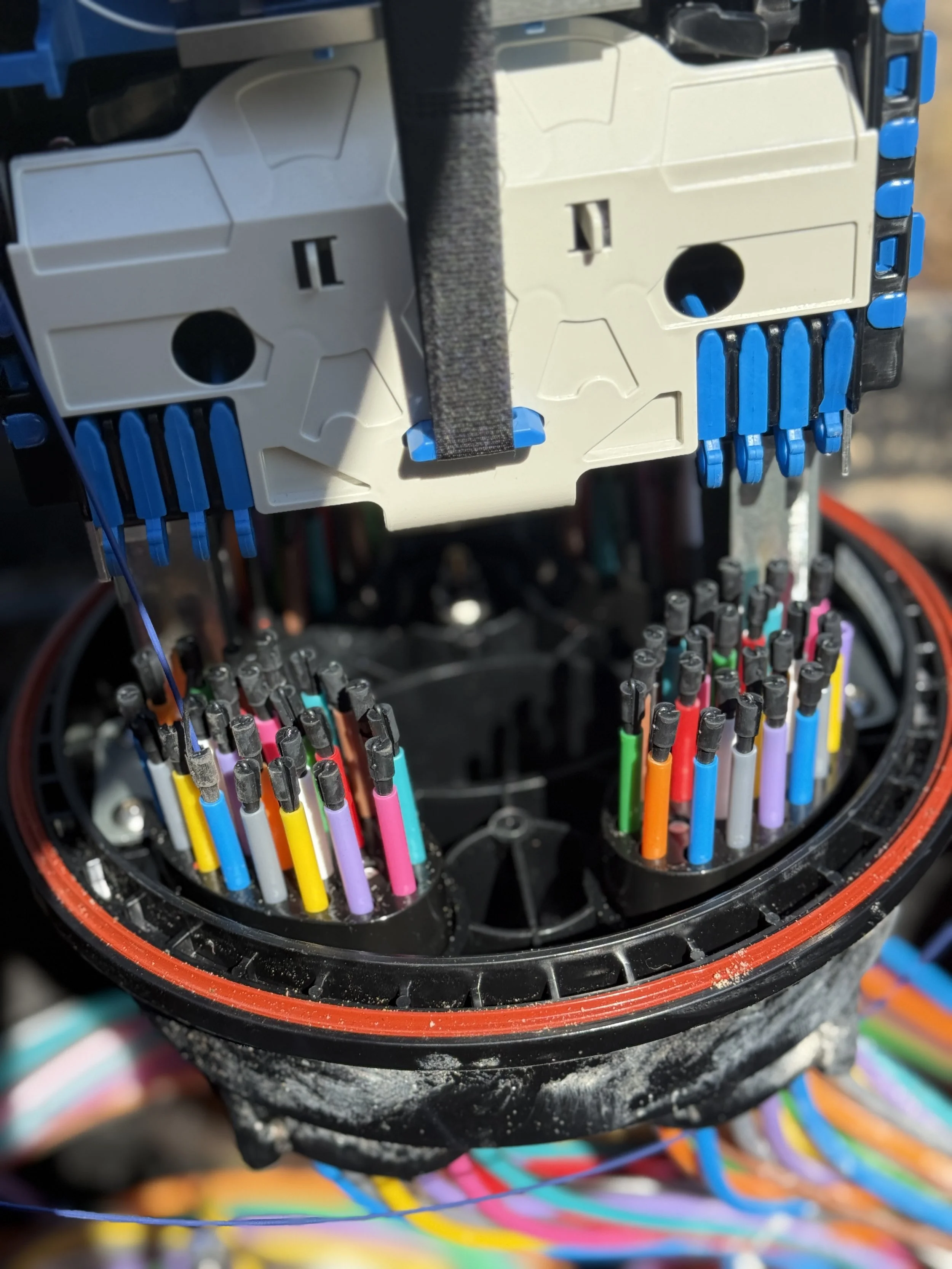

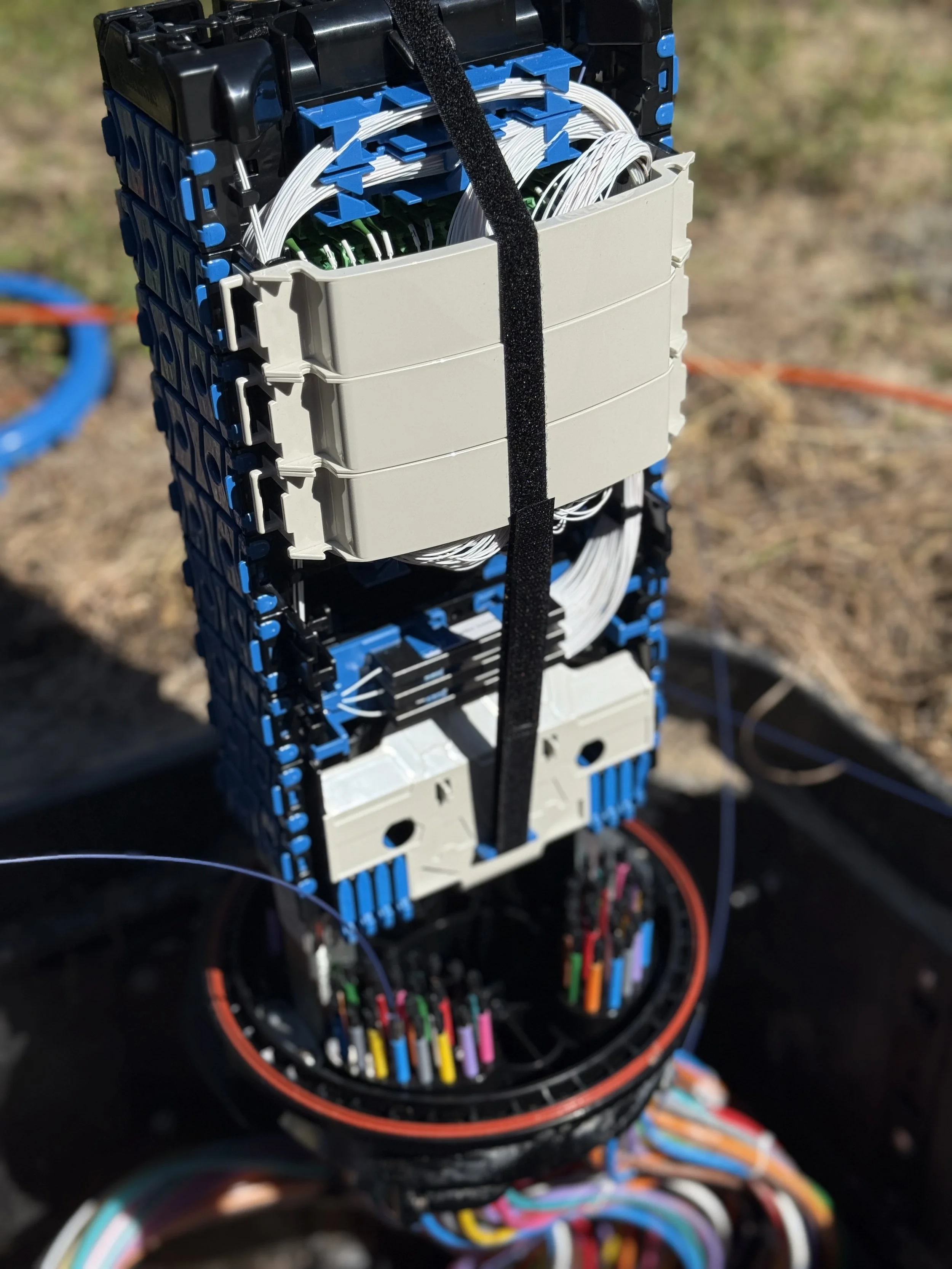

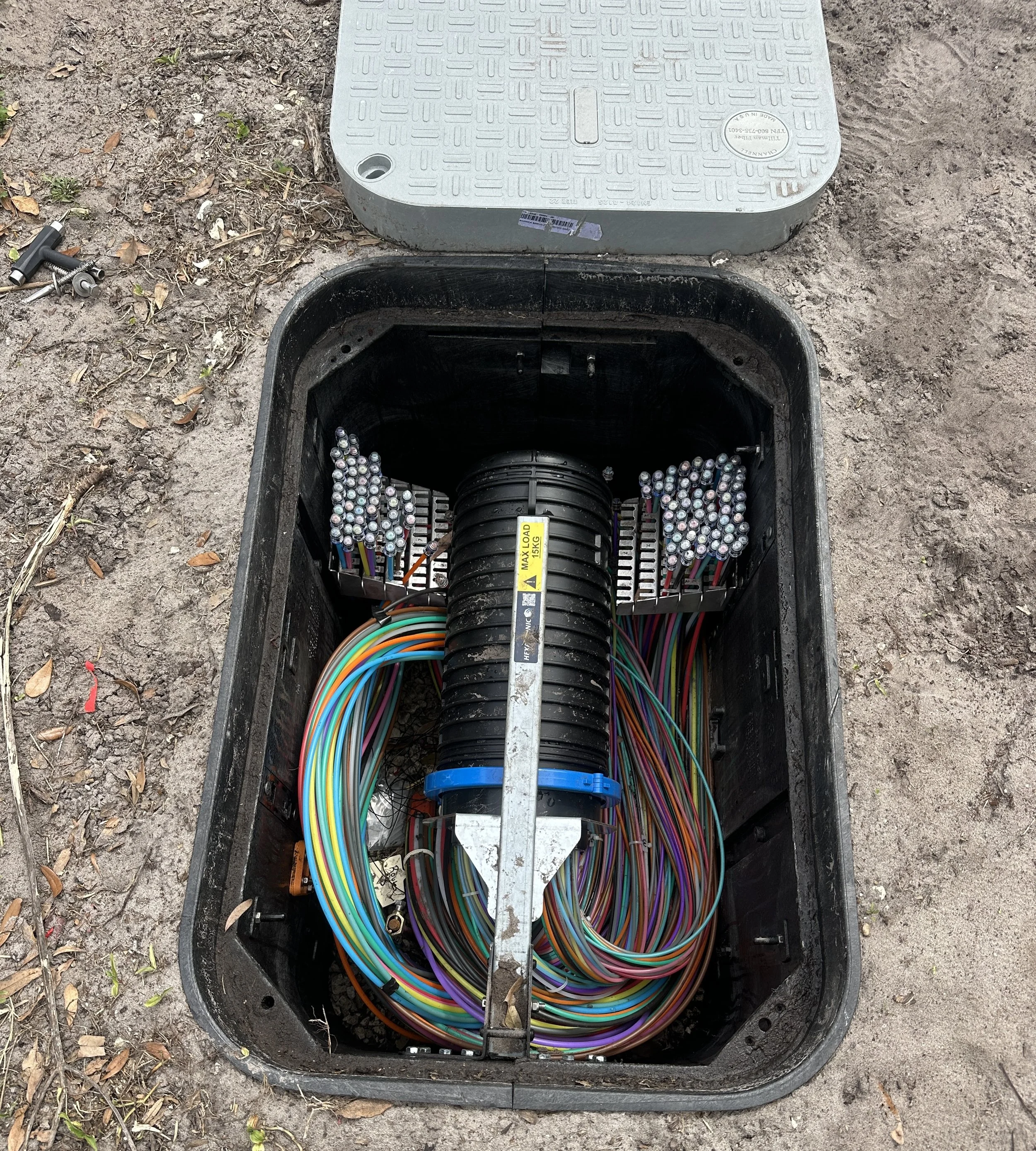

Our works underground construction

Blowing and installation

What can happen if the work is performed by an unscrupulous contractor

-

Excessive pressure or friction can cause microcracks, kinks, fiber breaks, and, as a result, signal loss, frequent disconnections, and the need for replacement.

-

Failure to check pipes for cleanliness and test them with a lead thread before installation, incorrectly selected pipe diameter may cause cable jamming

-

Outdated and incompatible equipment increases work time, frequent downtime, and increased air costs. Work time may increase by 2-3 times.

-

Ignoring safety protocols can lead to emergencies such as gas leaks or static electricity, which can result in injuries to personnel and fines for violating regulations.

-

Lack of knowledge prevents the cable from being secured properly, leading to shifts when the soil settles and breaks over time.

Our advantages

-

Precise equipment adjustment and damage prevention: we use professional equipment with pressure control, which allows us to maintain the integrity of the cable.

-

High efficiency and reduced installation time: we plan purging by segments and test pipes. This speeds up the installation process and reduces downtime and project costs.

-

Compliance with safety and environmental standards through the use of grounding, ventilation, and monitoring. We use certified equipment.

-

Post-blow testing for leaks, coupling fastening, documentation preparation, and quality assurance: guaranteed line durability – up to 25-30 years

-

Comprehensive optimization and consulting at the stage of selecting the type of cable and accessories: increases network bandwidth and resistance to interference

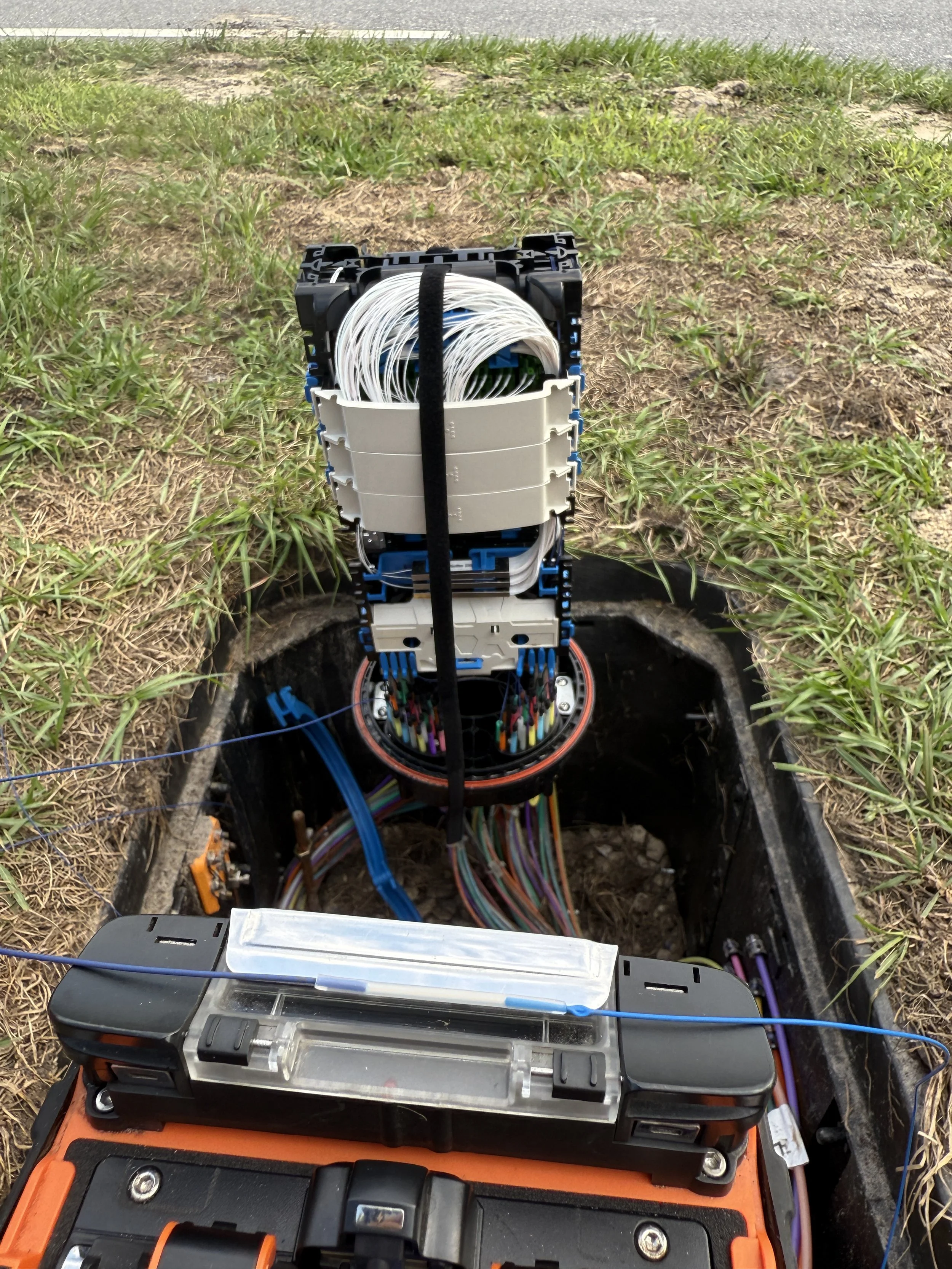

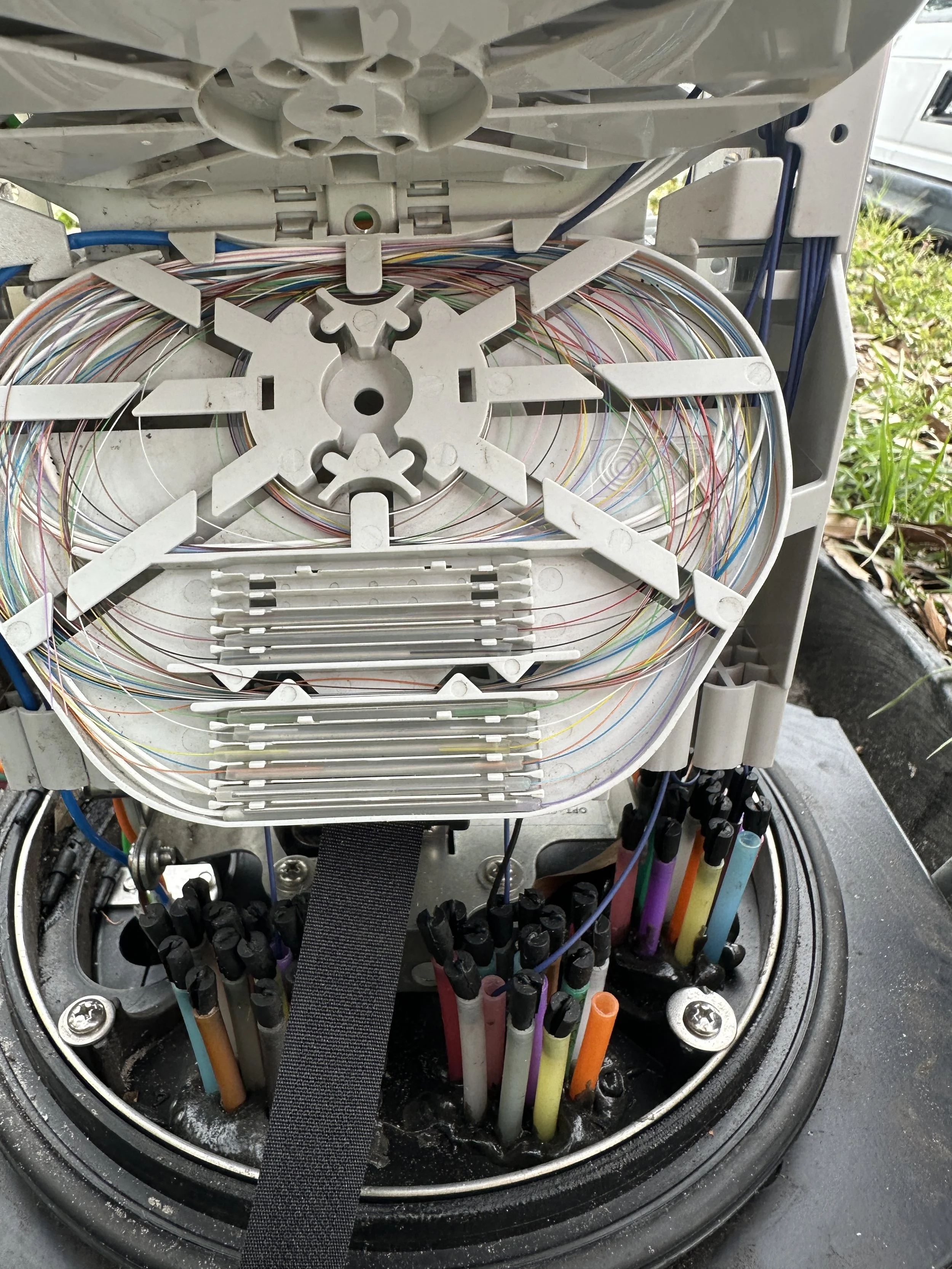

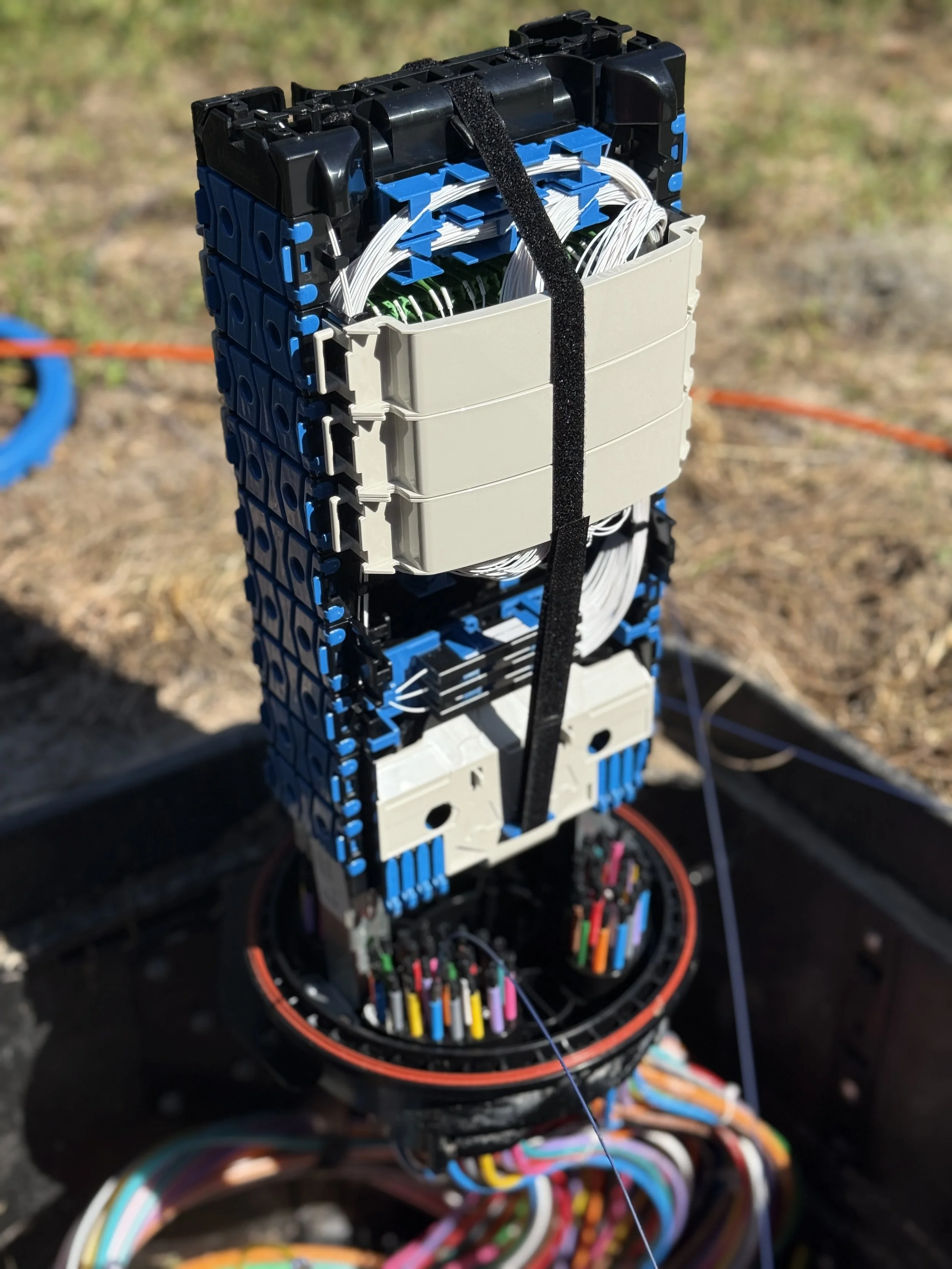

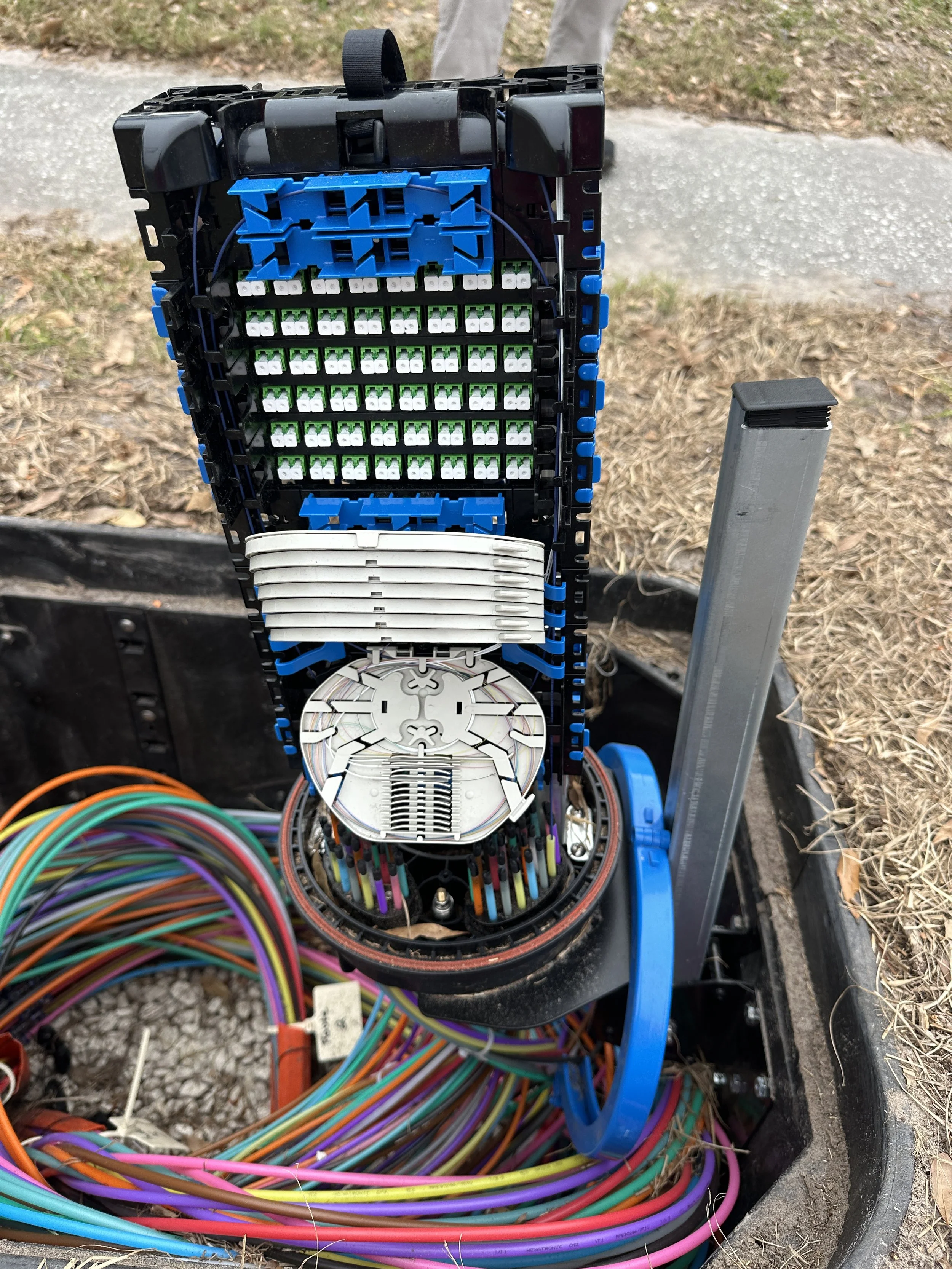

Photos of our blowdown and installation work

Distribution and connection

What can happen if the work is performed by an unscrupulous contractor

-

Occurs due to poor-quality welding or mechanical connection, can reduce signal speed by up to 50% and cause network interruptions.

-

Lack of knowledge about standards and the use of cheap connectors leads to dust or dirt in the contacts and complicates connection.

-

Failure to observe the minimum bending radius and the use of coarse tools may result in damage during fixing.

-

Ignoring protocols, lack of protection against moisture, mechanical damage to markings increase risks

-

The risk of hidden defects in the distribution system increases, and problems are detected later, after launch.

Our advantages

-

Minimal signal loss thanks to precise connections using professional welding and mechanical connectors, no degradation in splitters

-

We select the right connectors and ensure seamless connection to ONTs or routers, which increases bandwidth and resistance to interference.

-

We use insulation, grounding, and fastening to minimize the risk of fire or mechanical damage: a safety guarantee for 25+ years.

-

After connection, splitters and connections are tested, with a full report on losses. We provide a warranty for our work.

-

We select the optimal network configuration, integrating it into the existing infrastructure, which minimizes the return on investment.

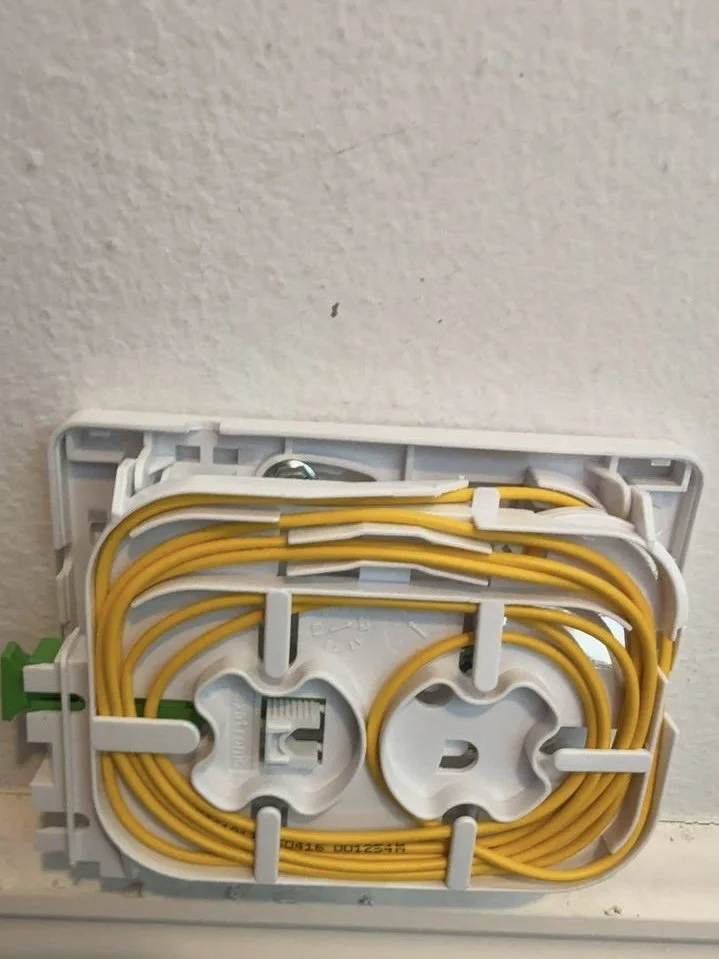

Our cases distribution and connection

Repair and maintenance

What can happen if the work is performed by an unscrupulous contractor

-

Problems are detected late, causing prolonged network downtime and loss of revenue: without accurate diagnostics, repairs are delayed.

-

Poor quality repairs, repeated breakdowns, the need for intervention every 3-6 months, which may be due to the use of cheap materials.

-

Associated with frequent repairs, unplanned trips, lack of maintenance, lack of knowledge, use of ineffective methods.

-

Ignoring protocols often leads to injury, and in damp underground conditions, it poses a risk of short circuits.

-

Repairs do not meet standards, resulting in fines from regulators or refusal to certify the network.

Our advantages

-

Quick localization and repair of damage: we use testers and locators for accurate diagnostics, restoring the line in 1-4 hours.

-

High-quality repairs with minimal recurrence: we use professional welding and protected couplings: the service life of connections is up to 20-25 years without breakdowns.

-

Savings on preventive maintenance: thanks to annual inspections and optimization, costs are reduced by 30-40%.

-

Compliance with safety and environmental standards: we use standardized solutions and guarantee uninterrupted operation.

-

Complete documentation and legal support: after repair, a detailed report with tests and an updated network diagram is provided, along with a 1-2 year warranty.

What repair and maintenance look like

Full cycle of work

We are ready to provide services ranging from laying trunk lines to directly connecting end customers. This significantly speeds up the work in case of unforeseen situations, such as damage to lines by other construction companies. The basis of our success is multi-level quality control and full compliance with project documentation. All work is performed within the time frame agreed with the customer. This minimizes the risk of problems arising after the lines are handed over to the customer. A professional approach minimizes the risk of errors and rework.

We use HDD rigs, microtrench cutters, compressors, and fiber optic cable blowing machines designed for Hexatronic Stingray fiber optic cable. Our teams are equipped with fusion splicers, OTDRs, optical power meters, and all necessary microtrench fittings, FDH components, and output equipment.

We adhere to modern standards in technology and work sequence

Service area

We serve Tampa and the surrounding areas of Florida, working with single-family homes, multi-unit complexes, and commercial properties. We handle new construction, network upgrades, and repairs to existing Hexatronic underground networks.

Tampa

Largo

Clearwater

Sarasota

Land O’ Lakes

Wesley Chapel

Lakeland

Clearwater

St. Petersburg

Brooksville

Riverview

Orlando

Contact Information

KING OF FIBER SOLUTIONS

5005 W LAUREL ST

STE 100-3125

TAMPA, FL 33607

(813)708-8010

Follow us on social media